How to Choose a Concrete Treatment: The What, Why, and How

Concrete treatments are an easy and effective way to improve the quality, durability and beauty of a concrete floor. There are an array of options available for commercial and residential use. These treatments can be applied to newly poured concrete floors and pre-existing concrete surfaces.

Types of Concrete Treatments

Concrete treatments can be added as part of the curing process or afterward to achieve a desired style and add durability. Densifiers and cures can be applied before, during or after the curing process to make the final surface harder and more resistant to dust, dirt, grime, scaling and freeze-thaw. Sealers and guards add surface hardening to resist against abrasion, freeze and thaw damage and stains. Coating treatments can protect installed floors from stains and abrasions, as well as permit vapor transmission to reduce problems like efflorescence. Specialized concrete cleaning products can also enhance the performance of treated surfaces while effectively lifting dirt and grime away. Certain formulas even fight issues caused by pH imbalances. High tech formulas can offer advanced concrete protection and treatment to resist common concrete problems. The advantages of using these treatments include improving the longevity of concrete surfaces and easy application. VOC-compliant formulas may also support LEED points.

Why Apply a Concrete Treatment?

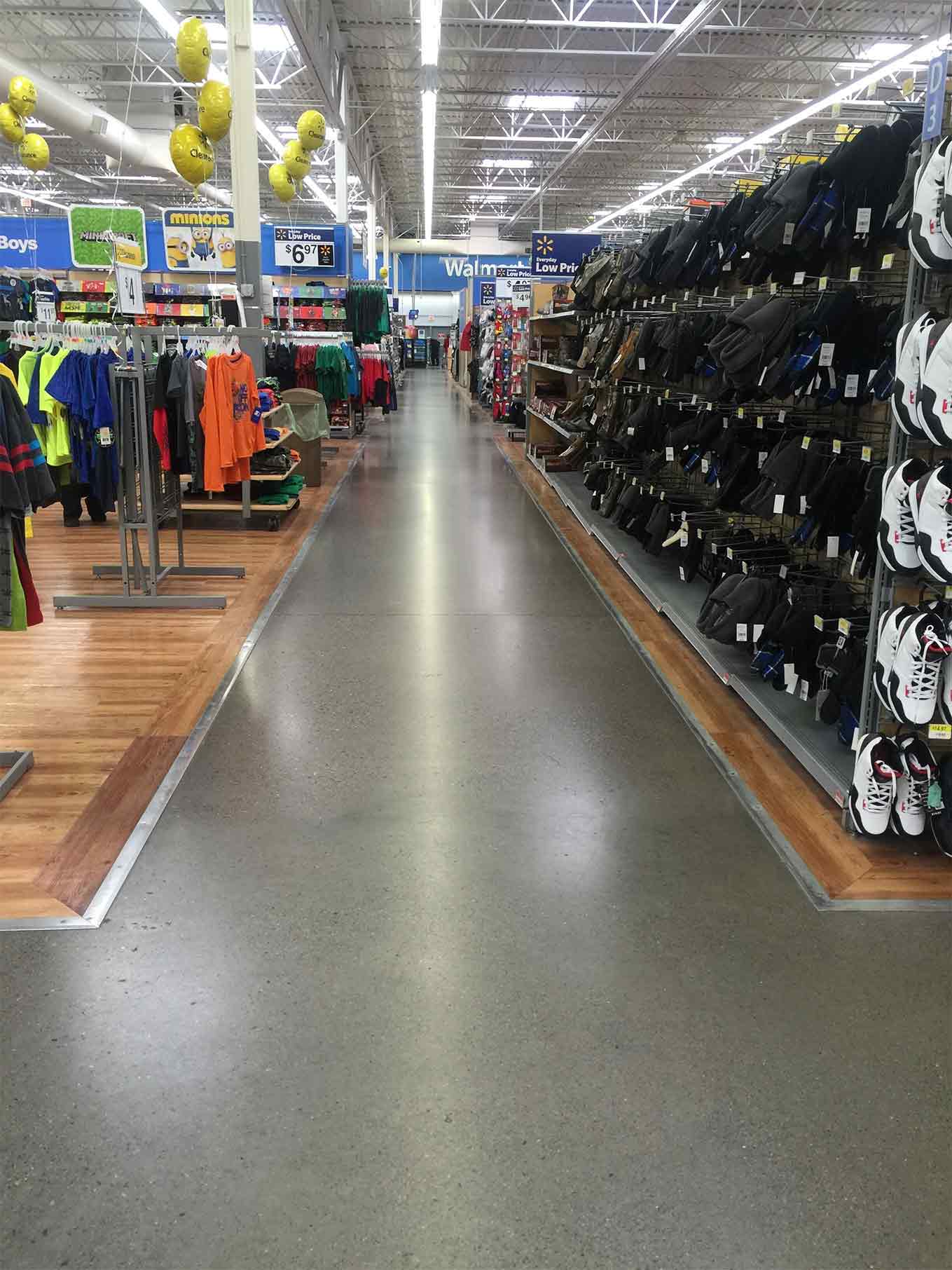

Floors set the tone for the overall look of a space, whether it’s commercial or residential. Using concrete treatments to deliver warmth, illumination and creative flair while still enjoying the benefits of concrete’s durability can provide a beautiful and easy-care floor. A concrete formula can protect the porous concrete from ordinary spills that stain, mold and mildew, dust and grime, abrasions, flaking and efflorescence. Some treatments, like polishing, coatings and epoxies, can increase the concrete’s natural resistance to wear and tear and reduce maintenance costs.

How to Choose a Concrete Treatment

The designed use of the space is a primary factor in choosing a concrete treatment. The needs of a commercial warehouse or manufacturer will be much different than a residential homeowner or institution, like a school or hospital. Factors include the amount of concrete to be treated, geographical location, intended use and whether it’s a new or pre-existing surface.

When developing a budget for the concrete treatment, use a coverage planner to estimate the costs and materials needed. Online concrete calculators can assist in determining the number of square feet of concrete to be treated, and the number of ready mixed concrete bags needed for a concrete slab, concrete footing or concrete column, if these will be new installations. In order to use these calculators, you’ll need to have the length, width and depth in linear or metric units. Talking to a contractor and already knowing the square footage of concrete or volume of concrete to be treated is useful; share the measurements you’ve already taken, too. Being able to share the number of bags of concrete, the width of the footing and other details can help your contractor provide the best estimate, whether you choose ready mix or custom made concrete.

Other factors that go into choosing a concrete treatment include budget. A project may be a stand-alone upgrade or part of a structural rehab. The existing condition of the concrete surface may also come into play. Some surfaces will require extensive prep work while others may only need a thorough cleaning with a Pentra heavy-duty cleaner. Depending on the concrete treatment chosen, enough time will be needed to access the space, apply the treatment, and allow it to set before it can be walked on. Maintenance and visual appeal are also considerations. Even though concrete treatments generally make surfaces easier to clean, your floor will benefit from Pentra cleaning solutions specially formulated to clean and strengthen concrete floors.

Curing concrete can be a labor-intensive and time-consuming process when traditional methods like water curing are used. Because it’s so important to control the moisture in the concrete, a reliable curing method must be used before any additional concrete treatment can be applied. An improperly cured concrete surface, because of plastic sheets or higher temperatures, for example, can lead to future problems with epoxy coating, polishing and overlays like tile or hardwood. That’s why a chemical membrane cure may be the best solution. Not only does it effectively manage the curing process, but it also hardens the concrete surface. Densifiers can be applied before or after curing to harden and improve the durability of a concrete surface.

- Pentra®-Sil (H) is a dust-proofing hardener made for concrete slabs and tilt-up construction. Treated surfaces are more abrasion resistant while also protecting against water and staining.

- Pentra®-Sil (HDS) is a hardener, densifier and sealer designed for integrally colored, dyed, stained and polished concrete, especially on worn or damaged surfaces.

- Pentra®-Sil (IH) is an impregnating hardener used in polishing terrazzo, stone and concrete surfaces.

- Pentra®-Sil (HD+C) is a hardener, densifier and curing compound engineered with Responsive Separation Technologyô (RST).

- Pentra®-Sil (244+) provides salt protection as well as dust-proofing, hardening, densifying and sealing of exterior concrete surfaces.

- Pentra®-Sil (NL) is a premium lithium high performance densifier for concrete surfaces. This high solids formula provides maximum hardening to improve abrasion resistance and reduce dusting.

- The VOC-compliant, ready-to-use Pentra®-Cure (PW) agent forms membranes and cures emulsified paraffin wax concrete by forming a barrier against moisture loss, without staining concrete surfaces.

- Pentra®-Sil (AC) alkalinity control hardener reduces efflorescence and slab sweating.

- Pentra®-Shield hardening densifier with anti-scale and freeze-thaw protection is ideal for outdoor concrete surfaces while also reducing spalling and scaling.

After curing the concrete, these specialized concrete treatments will beautify and add durability to the concrete surface as well as increase abrasion resistance, reduce skid marks and more. Treated surfaces are more stain-resistant, and exterior surfaces can better withstand the freeze-thaw cycle.

- Pentra®-Finish (HG) is a lithium-based sealer that delivers an advanced high-gloss stain and wear protection. It’s applied to smooth finished concrete surfaces including integrally colored, dyed and stained polished concrete surfaces.

- Pentra®-Pel (SI) stain guard is a surface impregnator with advanced micro-bonding stain protection for interior and exterior surfaces.

- Pentra®-Guard (EXT) is an exterior surface hardening and protective sealer that’s resistant to abrasion, flaking and peeling.

- Pentra®-Shield concrete surface hardening densifier offers anti-scale and freeze-thaw protection for exterior surfaces.

- Pentra®-Sil (244+) provides salt protection, dust-proofing, hardening, densifying and sealing for existing concrete surfaces.

Coatings enhance the look and performance of concrete surfaces by delivering long-lasting color, then sealed for protection. Coatings are available in a variety of colors while sealers are clear and enhance the color.

- Pentra®-Protective Coating (PPC) is an industrial micro-coating and surface hardener for indoor and outdoor use.

- Pentra®-Paint (LM) safety and traffic marking paint does not peel or flake and can be enhanced with glass beads for reflective needs.

- Pentra®-Finish (HG) is an advanced high-wear gloss stain and wear-protection lithium sealer.

- Pentra®-Guard (EXT) exterior surface hardener and protective sealer that dries to a premium wet look.

Concrete that’s been treated with sealers, guards, polished finishes, epoxy coatings, acids and dyes may require special cleaning products. Choosing the right cleaners can maintain the look and performance of a concrete surface while effectively lifting dirt, grime, stains and soil. Cleaners can also help reduce common problems present in concrete floors, like sweating.

- Pentra®-Clean (CR) cleaner restorer uses a nano-lithium formula to remove dirt and grime while hardening and protecting concrete floors for added performance, durability and longevity.

- Pentra®-Sil (C&N) concrete cleaner and neutralizer uses lithium technology to minimize efflorescence and surface sweating.

- Pentra®-Clean (DC) daily cleaner has a neutral pH and effectively cleans dirt and grime from concrete and other stone and tile surfaces.

Some concrete surfaces like decorative concrete may present conditions that require special care. Specialized products can improve the condition of concrete slabs and other surfaces as part of general maintenance and upkeep as well as advanced concrete treatments.

- Pentra®-Sil (AC) alkalinity control hardener also densifies concrete surfaces and improves resistance to abrasion.

- Pentra®-Sil (C&N) concrete cleaner and neutralizer stabilizes the condition of concrete surfaces, reducing alkalinity problems through a chemical reaction.

- Pentra®-Sil (PCF) liquid pore and micro-crack filler prepares concrete surfaces for grinding and polishing by filling in the pinholes created from concrete polishing.

- Pentra®-Pel (SI) surface impregnator with advanced micro-bonding stain protection densifies and seals surfaces after the concrete has hardened.

- Pentra®-Shield concrete surface hardening densifier with anti-scale and freeze-thaw protection minimizes scaling and spalling.

- Pentra®-Melt premium ice-melt, anti-icer and de-icer is designed to treat concrete surfaces in cold weather without damaging surfaces or leaving messy residue behind.

There are many factors that go into choosing the right concrete treatment, from the curing process to cleaning and restoring existing surfaces. Consider problems like curing temperatures, curing time, spalling, scaling and efflorescence when selecting a concrete treatment for your needs. In some cases, water evaporating too quickly may be an issue; in others, compressive strengths and spalling might be an issue.

Contact Convergent Group for a full line of Pentra products that will fit your needs, including curing and post curing treatments.